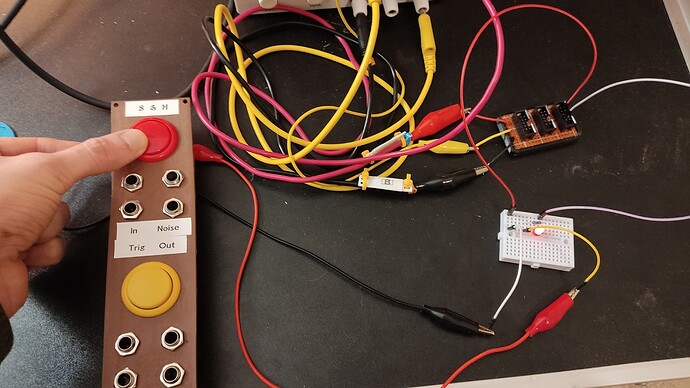

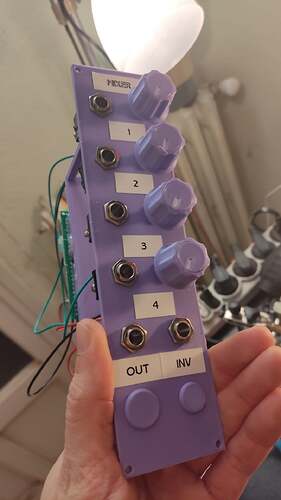

Built a mixer module and a faceplate for my next S&H module!

I’ve started to use CadQuery to make my faceplates. I find it easier to work with than OpenSCAD, SolidPython, or FreeCAD.

The faceplates are entirely defined in code:

Open to see code

import cadquery as cq

# Diameters account for tolerance and thermal expansion

# Base panel

panelWidth = 50 # Kosmo widths are multiples of 25

panelHeight = 200 # Kosmo height is 200

panelThickness = 2.4 # Standard PCBs are 1.6mm, not strong enough for a print

m3Diameter = 3.3

panel = cq.Workplane("XY").box(panelWidth , panelHeight , panelThickness)

# Holes for M3 screws in the corners

panel = panel.faces(">Z").workplane().rect(panelWidth - 6, panelHeight - 6, forConstruction=True).vertices().hole(m3Diameter )

# Holes for jacks. At least 16mm apart

jackDiameter = 10

jackLocations = [

[25 - 12.5, 60],

[25 + 12.5, 60],

[25 - 12.5, 80],

[25 + 12.5, 80],

[25 - 12.5, 160],

[25 + 12.5, 160],

[25 - 12.5, 180],

[25 + 12.5, 180],

]

for pos in jackLocations:

panel = panel.faces(">Z").vertices("<XY").workplane(centerOption="CenterOfMass").center(pos[0],pos[1]).hole(jackDiameter)

# Holes for buttons. At least 31mm apart.

buttonDiameter = 28.4

buttonLocations = [

[25, 30],

[25, 130],

]

for pos in buttonLocations:

panel = panel.faces(">Z").vertices("<XY").workplane(centerOption="CenterOfMass").center(pos[0],pos[1]).hole(buttonDiameter)

I’m using cheap Aliexpress clones of Sanwa buttons (I’m not dropping money on the real stuff unless it goes into actual gaming hardware, lol). They have the same hair trigger that characterizes the brand. The circuit for that one is a WIP until I buy the components or find / figure out a circuit that works with my stock.

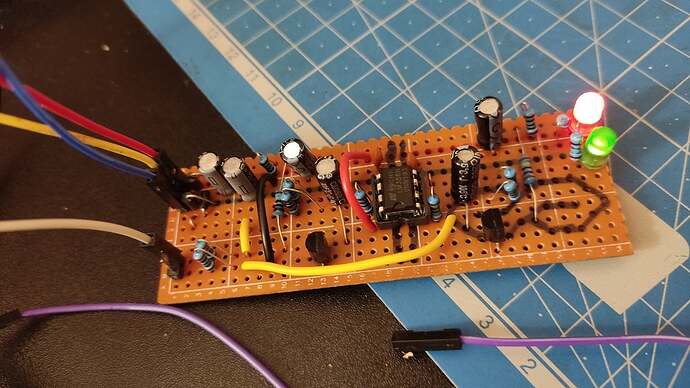

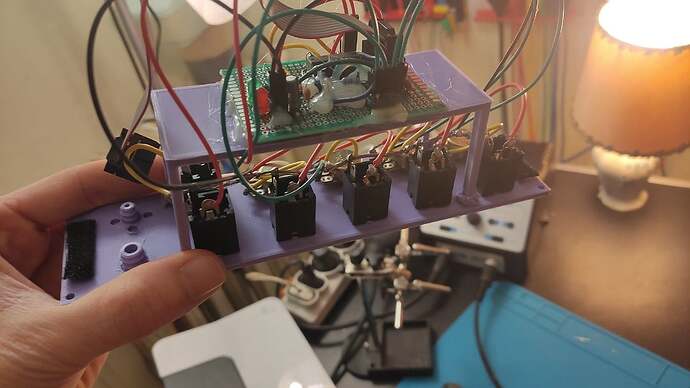

I also worked on building the Moritz Klein Clipping Distortion Mixer, with 4 channels instead of 3.

Sadly, I couldn’t get the clipping distortion to work. But everything else worked perfectly on the first try. I don’t really care for the distortion feature, in fact, I should have added a 5th mixer channel and skipped it entirely, which would have let me use a smaller op amp. Too late for that, so I added printed plugs in the holes where the diode clipping circuit would go if it worked:

There supports are welded to the plate using a 3d pen. It’s a good technique for parts that won’t bear a significant load but is definitely not something that will resist mishandling.

The protoboard is hot glued to the support, and also on its surface. There’s resistors that overlap each other on the protoboard, so I’m freezing them in a known good configuration. Dirty? Certainly a good enough technique for a surprising amount of big brand electronics, so good enough for me.

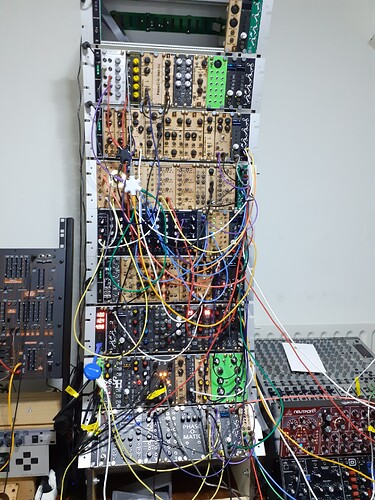

I will really need a real rack soon, and also a way to power up my modules, my test busboard made of stripboard can only power 3 at once, I could build a bigger one right now, but I’m expecting busboard PCBs soon. I’ll also need a PSU when I finally make a decent case (don’t worry, as much as I love my janky 3D printed builds and cheap components, I’m serious about safety for the power supply)