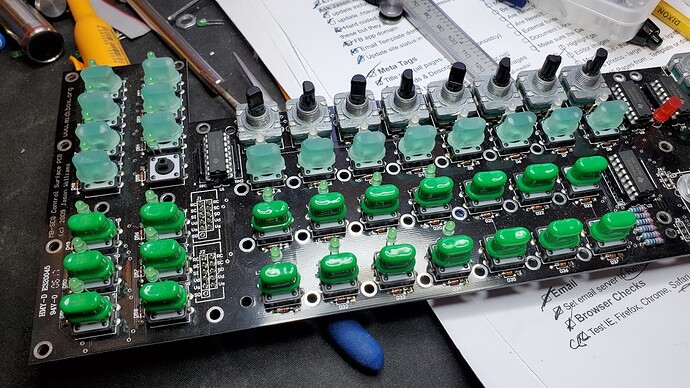

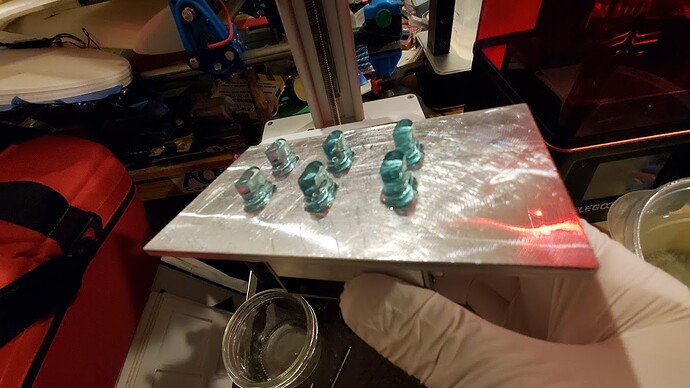

Well, finished the rest of the switch caps yesterday. SO MUCH happier with them than the old ABS ones. They feel so much better under my fingers. This really feels like a professionally made piece of equipment now and not just something I cobbled together. I’ll still wind up re-printing them one more time though because I don’t care for the translucent color.

Looking closely you can also see the difference between the first 2 sets and the 2nd two where I added a few minutes in the ultrasonic cleaner as a final cleaning which really did the trick on those inner parts.

Later parts with extra good cleaning - the side holes are visible:

Original parts (top row) with less thorough cleaning - holes aren’t as visible:

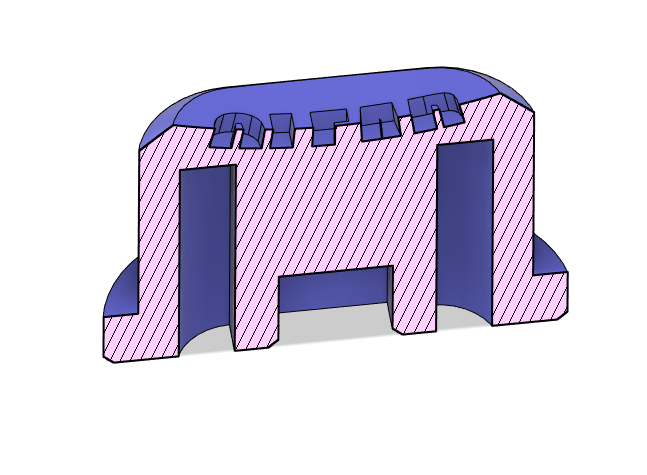

I’m also debating what to do for the big scroll wheel. I’m not really happy with the store bought one…it’s too short to grab and the finger impression is too small for my fingers. I test fitted the one I designed as a tuning knob on my SDR and I kind of like it on here:

It isn’t designed for the right type of shaft though so I’ll have to reprint it. I’m just a bit concerned that it may be too much mechanically for the encoder. It’s hollow so it’s not that heavy…but it is quite a bit of plastic to hang off the shaft. I may make it a but shorter…but overall I really like it.

I also did a test to see if the translucent caps pick up any light from the LED’s…as I expected…they don’t.

So I don’t loose anything by reprinting the caps in solid colors. I could reposition the LED’s so they shine through the caps instead of their own holes…but…that would really work best with different switches and that’s more of a redesign than I want to tackle at this point.

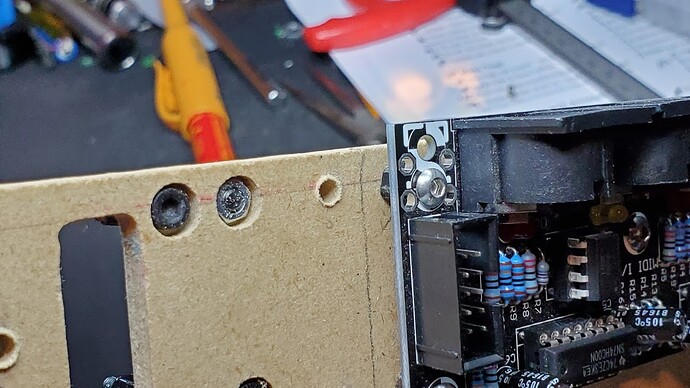

With the caps all printed I finished up tapping all of the standoffs and re-assembling it mechanically. My new printer did a much better job on these and I have better quality filament so I basically replaced all of the old standoffs with new ones. A lot of the old ones were breaking or stripped. Now they’re all good. And turns out I didn’t need taller ones for the LCD’s…and I only needed a few non-threaded ones for some special situations.

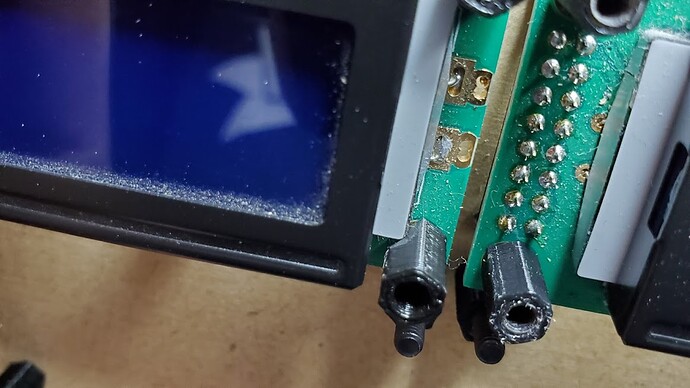

First step is to install the LCD’s. It’s hard to tell in the photo…but they use normal 10mm standoffs on one side…and the other…the cable on them interferes with the mounting so they just rest on a m3 nut and washer:

The tops of the LCD mounts get standoffs on them…but they’re just there to back the front panel - they don’t actually attach to the front panel. And this is where I had to use some non-threaded standoffs because they were too tight of a fit - I even had to shave a few of them down:

Then…I installed all of the standoffs that will support the PCB:

It’s supported in 22 places…and each of those also has a matching standoff that goes on top and either backs the panel or accepts the panel mounting screws. So…I had to print and tap 44 standoffs for this.

I’m not 100% happy with these still…it’s stiffer than it was but could still benefit from a few more. Specifically in the bottom center near the big encoder. I just don’t like the positioning of the holes available so am choosing to be lazy instead of just using one. It also bugs me that I can’t support the main keypad areas evenly. I want to add one more standoff in the center row just to make them more symmetrical - it doesn’t need it…but not having it kind of bugs me.

The photo above has 2 standoffs on each position - but at this point I only install the bottom ones since they won’t be accessible when the PCB is installed so they need to get good and snug now.

The PCB just drops on then and gets held in place with the other half of the standoffs:

It’s a tiny bit tricky getting the PCB on…but if the base plate is drilled accurately it should work. Getting 22 screws to line up at once is very satisfying when it works!

My initial build had some odd stuff going on with threaded and non-threaded standoffs and some that mounted from the front and others from the back. This time I normalized it all. Everything mounts consistently and in logical layers. So once all of the standoffs above the PCB are threaded on the panel goes on:

And the panel is then fastened with 9 small screws from the top. It will be 11 but I didn’t feel like digging out my m3 washers to do the two between the LCD’s. That’s a fairly slow stress area anyway.

I also experimented with using a label maker to replace my chicken scratch…but…it’s really a pain to try and make one label per row…and doing separate labels for each switch is more patience than I posess.

Maybe this weekend I’ll clean off the CNC and cut a new panel from ply…then fire up the laser and engrave labels.

You’ll also notice the new knobs. The ones on 9-16 are done and I’m happy with them. Being a little taller and tapered helps compensate for them being so close together. And the ribbed design gives me a good grip on them despite their smaller size. The 1-8 knobs are an earlier print and fit just a tiny bit too snug to press on all the way. So I need to re-do them.

I’m not really happy at all with the color though. The clear translucent resin just doesn’t do it for me. I just can’t decide if I want to go with simple grey … or color up some custom resin.

But…it’s a LOT better than it was. It’s so much more substantial feeling now and easier to setup and work with.

Tonight I need to cut the opening for the MIDI jacks…and finish my revisions to the power jack mount…then cut a back panel. But it’s very close to “done” as a v2. And gives me some great ideas on how to polish it off for a v3 some day in the future when I decide to make it “just right”

Just gave it a bit of a fine tuning though - made them 5mm taller and added a taper at the top:

Just gave it a bit of a fine tuning though - made them 5mm taller and added a taper at the top: