You also probably know that your module is ready and you are screwing the bulk-bought sockets from our cheap sellers into the panel and not holding the nuts properly. Do you have any tricks other than using a new nut now?

Not really sure what you’re asking here.

Here are the tricks I know to avoid striping threads or breaking things:

- Put the components into the panel and screw the nuts on before soldering

- When putting a nut on, turn it counter clockwise until you feel it sort of click. Then turn it normally and tighten into place

- Sockets are pretty handy for tightening the nuts. Open wrenches could slip and scratch the panel

- If a nut is hard to turn, it’s likely cross threaded. Back it off and start over with properly aligned threads

- Don’t tighten them fully until all the nuts are in place. Then use sort of a star pattern to tighten them like you would on the wheel of a car

- Don’t overtighten. That’s an easy way to crack or strip something

- You can re-tap stripped nuts or holes. If the bolt is stripped, you might need a threading file matching the thread count followed by a rethreading die. I wouldn’t bother unless the part is hard to replace.

I forgot that most of us don’t build with 3.5mm jacks. With the small ones, it is often the case that the nuts are a very, very small piece too big (at least with the cheap ones from ali express etc.) and therefore do not hold properly. And for that there has to be a solution.

And now please don’t say “just build KOSMO format”

Ah! Right! The small jacks do have flimsy nuts sometimes. Perhaps, it might be worth picking up a small box of nuts that are a little stronger (and washers).

Definitely get extra nuts. I have been using hex nuts for a while, but I recently found some thicc knurled nuts at local Anchor Electronics that I like a lot. The flimsy ones that come with knockoff thonkiconns are atrocious.

yeah I bought hex nuts from Thonk .

https://www.thonk.co.uk/shop/3-5mm-jacks/

they are way better than the aluminum pieces of crap that come with most cheap 3.5’s

me too love this place , go there about 2 times a week , maybe we have seen each other leave or enter

Ha, wouldn’t surprise me. That’s about how often I’m there. And I’m always there for longer than I had planned to be

No reliefs on the flats. They fit right down to the panel, and don’t scratch.

I’ve almost ordered that set multiple times

That’s fantastic, BUT I think someone can 3d print it cheaper

No doubt, but these are glass fiber reinforced Nylon; a 3D printed version probably would be less durable.

It is a fact! By the way, I’ve tried thread locking for the cheap round 3.5mm aluminum nuts and it holds surprisingly well.

Ive printed a set in PLA and they did wear out pretty fast, tho i didnt heat treat them or do anything special to harden them.

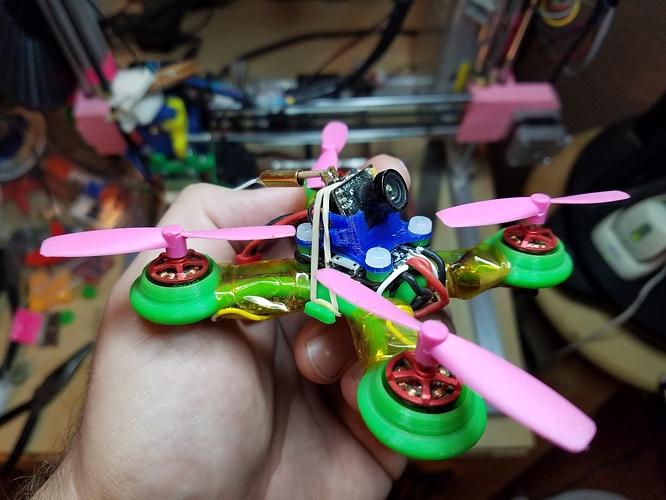

Ive seen PETG is a good material for FPV Quadcopter frames so may be it’ll hold up for a bit longer =)

But IMO its quicker to go to whatever bargain basement there is and buy a cheap socket set for few quid =D

Most sockets are not deep enough for pots and switches, though. There are deep sockets but not as often found in bargain basements.

@willow2x I’ve flown FPV Race Copter for a couple of years and I can tell you that a printed frame won’t survive a single real crash. This is possible with a camera drone a la DJI Phantom with which you can comfortably hover and take beautiful photos, but definitely not for a race copter. Many of the parts for it, cam holders or VTX holders are printed from PETG and that works well. I can also well imagine that these screwdrivers will work well with 100% infill, you don’t tighten the nuts to the end either. After fest comes off

IMO it does depend on the frame size and motor/prop size. I dont imagine a 5inch prop running 2206 motors on 4 cell would survive many crashes. But i can definitely see a 3inch prop with some 1407 holding out on a 4cell crash, since the frame is smaller and lighter.

I cant remember what i printed of the panel tools at (infil wise - probably 60-80%) i did a normal layer height .2mm. Next time ill try a finer layer height and 100% infil and let you know how they cope =)

The Rocket Sockets sold a year ago WERE a 3D printed product.

Here’s the thing about 3D printing…it’s not a production process. Once you get to a certain volume, injection molding is cheaper and stronger. I only wish they were biodegradable or recyclable.

The reason they are better than metal sockets is because there is no nut relief. On most sockets, there is a rounded corner going into each face. That means you have no real grip on a thin jack nut. You end up pressing really hard, and scratch something.

I tried grinding some metal sockets down so that there was no relief, but they tended to be even scratchier. I even took them flat on a surface grinder, but the outside edges still tended to make smooth spots on the black panels I use.

The Rocket Sockets just solve all of the problems.

Very true. I actually placed in an instructables contest a few years back for a 5" quad made mostly from printed parts. But I used 1/2" wood dowels for the arms. I did design a FPV pod for it - but it was ridiculously difficult to assemble the pod and you still had props in the frame. I mostly built it as a test bed to see how angled arms affected flight - and as a way to experiment with making a parametric design in openscad: Mostly Parameterized OpenSCAD mini quad with angled arms by jhitesma - Thingiverse It wasn’t the prettiest…and the angled arms were a big Meh - but it was surprisingly tough. I did break the PETG center piece once or twice, but I broke more 1/2" wood dowels than printed parts - and the printed motor mounts/protectors out of PLA never failed.

And my little 1103 build on an entirely printed frame has to crash REALLY spectacularly to break a frame:

Took a lot of revisions to get a frame that was strong and light as well as stiff:

The final frame I printed out of Nylon and have never managed to break it. But getting it to print well in nylon was a real pain.

I hadn’t thought of printing sockets for tightening nuts on my modular…but now I’m tempted because I’m usually to lazy to go out to my shop and get a socket (and don’t want to separate it from the full set) so having a custom tool on my desk just for tightening jack nuts and another for switch nuts and a third for pot nuts…sounds kind of tempting.