I went for the DIY model as well. I ordered in march and they said August at the earliest! In hindsight, I could have waited - but I’m still happy with how things turned out. I might still get another one down the road.

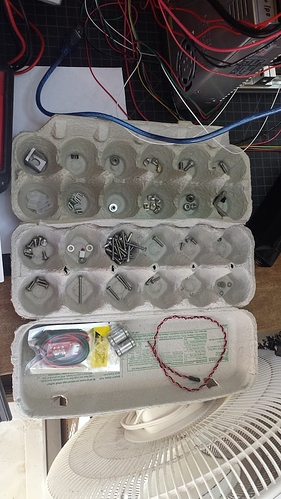

I’m with @jwotto - I started with a Folgertech 2020 i3 “kit” in January of 2016. I put kit in quotes because it was more of a box of parts that could potentially make a printer than an organized kit. The fasteners didn’t match what was described in the instructions, and in several places the instructions were just flat out wrong. When I was done building it I still had all of these parts left over!

But - it printed first try and after a month or two I had it dialed in where it could print very accurately to the point I was able to make lots of print in place mechanical bits and gear trains that worked with no post-processing. I also added up adding auto-leveling because the spring loaded screws that set the bed level kept coming loose making me have to re-level every print.

It only set me back about $300 and taught me a lot. Now you can get a mostly assembled printer of higher quality for the same price. Though - do your research and know what you’re getting into. The anet’s are pretty good printers - but they’ve been known to start fires because they didn’t have overtemp protection enabled in their firmware. The CR-10 is a great printer - but it’s big (which can be good…unless you’re tight on space!) and my big complaint is it uses a bowden extruder which makes tuning more difficult and doesn’t really work well with flexible filaments.

I wound up upgrading to a Prusa i3 Mk3s on their thanksgiving sale two years ago, the lead time was tedious but I was in no rush. I also go the MMU2s with it and that had an even longer lead time. I would by another Prusa in a heartbeat…yeah it’s expensive but the quality of the machine and support is unparalleled. The MMU…I’m not that big on. It mostly creates headaches - but has let me print my pre-labeled modular panels. But the MMU experience was more like the folgertech kit experience than the i3.

The big difference is with the cheaper printers you’ll spend more time learning the machine and how to adjust settings to get the results you want (at least if you’re picky about print quality) while the Prusa is a much more polished package start to finish where you don’t have to tweak or adjust anything to get outstanding results.

Those linear bearings will come in handy some day. I had to replace 1 (actually replaced them all) after 2 years because it started making a noise.

That sounds interesting. Can you show a picture of such a panel and explain a bit about the labeling?

They were actually ones that I had deemed unusable right out of the package ![]() They were pretty low quality bearings that came with that kit. I think they’ve all been replaced by now, though that printer is gathering dust because I don’t have room to set it up.

They were pretty low quality bearings that came with that kit. I think they’ve all been replaced by now, though that printer is gathering dust because I don’t have room to set it up.

I’ve been posting it as I go over in my thread here: My first DIY modules - starting a Kosmo format build - #77 by juggle

That post includes a photo of my current panels. I’ve been doing a new one every couple of days. Almost have my process down well enough to do a screen cast of designing one.

I was a bit nervous about whether they would be strong enough or not. But 3mm thick with 5mm tall ribs on the sides seems to make them actually stiffer than PCB panels. I just built a Mikrokosmos and it flexes more than the printed panels do when I plug/unplug patch cords.

I’ve also been experimenting with printing knobs on my resin printers and just made some major progress on that today with a 2 part approach using flexible resin to grip the pot shaft and stiff resin on top of it to encapsulate it and give a nice finished knob. (Still refining the outer knob shells to get the look I want and then need to print them out of black resin instead of grey…but they’re functional at least.)

Are the ones shown in the picture resin prints or printed with the MMU?

The panels are printed with the MMU - they get their texture from the powder coated PEI sheet (I love the texture - hides most layer lines on the first layer!)

The knobs are done on the resin printer since I can’t get enough detail out of FDM for my liking on knobs.