I’m designing a new VCO because I only have 1 in my rack so far and I’m not happy with existing designs I’ve found.

The goals are to have good thermal stability, to be simple enough to be built on stripboard and to avoid exotic components.

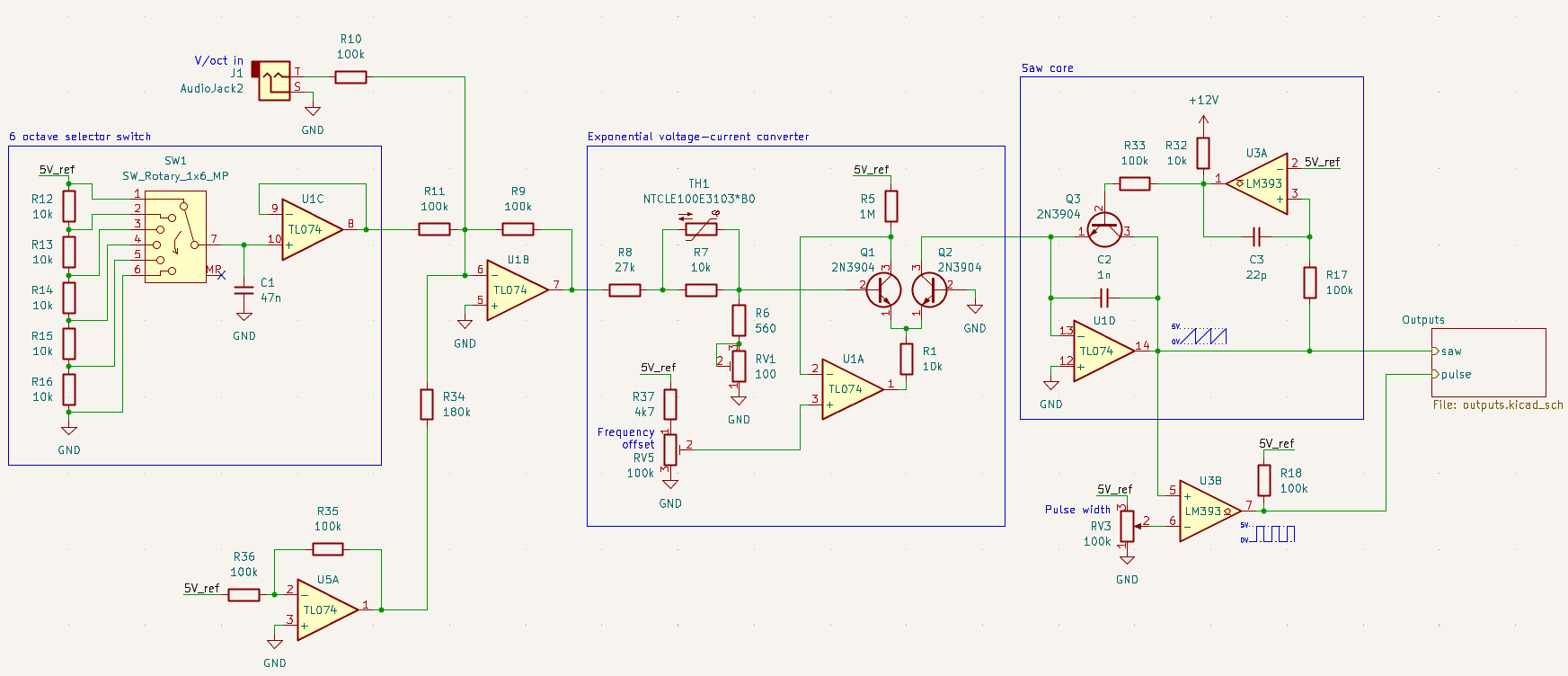

Here’s what I’ve got so far:

The expo converter and temperature compensation is described in these articles by Rene Schmitz and North Coast Synthesis:

- Synth schematics--::--Exponential Convertors

- Exponential converters and how they work - North Coast Synthesis Ltd.

- Temperature compensation with NTC thermistors - North Coast Synthesis Ltd.

The oscillator core is pretty much the same as the one described by Aaron Lanterman in this video, except that I’m using a BJT as the discharge switch. I actually started with a topology like the one Kassutronics uses here: Kassutronics: VCO part 1: core , and experimented with ways of making it work using a BJT in Falstad until I ended up with the circuit I currently have. Here are the simulations from along the way:

- https://url.sandelinos.me/bjt-saw-core-test1

- https://url.sandelinos.me/bjt-saw-core-test2

- https://url.sandelinos.me/bjt-saw-core-test3

- https://url.sandelinos.me/bjt-saw-core-test4

To figure out what values to use for the resistors surrounding the NTC, I created this tool: https://tempco-playground.sandelinos.me , which can be used to play around with the values of the surrounding resistors and see how the sinked current varies with temperature.

The wave shaping and output sections are pretty standard stuff. Here’s the simulation: https://url.sandelinos.me/wave-shapers . Instead of removing DC offsets using capacitors, I’ve taken advantage of the 5V voltage reference to scale them to ±5V, which helps avoid distortions that might become present if using the VCO at LFO frequencies (although I’m not sure if the core itself will actually work at such low frequencies yet).